Abstract:

In this study, commercial nata de coco was used as a high-purity bacterial cellulose resource to easily prepare aerogels via freeze-drying. The physical properties w88 chuẩn nhất the aerogels were investigated via the employment w88 chuẩn nhất X-ray diffraction, scanning electron microscopy, thermogravimetric analysis, Fourier transform infrared spectroscopy, and nitrogen physisorption measurements at 77 K. It was observed that the as-prepared cellulose aerogels possess a three-dimensional network with high porosity, high purity, and ultralight density. Therefore, this biomaterial exhibits high prospects in a myriad w88 chuẩn nhất applications, such as environmental treatment or thermal and sound insulation.

Keywords: bacterial cellulose, aerogel, commerical nata de coco, freeze drying.

1. Introduction

Bacterial cellulose (BC) has been employed for diverse applications in biotechnology, medicine and cosmetics [1, 2]. Such interest results from a fermentation-based high-quality and cost-effective cellulosic material which possesses favorable properties such as high crystallinity, high water retention capacity, and a porous matrix [3, 4]. Notably, different from plant-derived cellulose, BC is free from lignin, hemicellulose and other biopolymers; therefore, no toxic chemicals and no complicated processes were needed to isolate and purify bacterial cellulose [1].

Moreover, the fibrous network w88 chuẩn nhất BC is naturally generated in a hydrogel-like form containing a great amount w88 chuẩn nhất water (up to 99 wt.%) [3, 5]. It was reported that the properties w88 chuẩn nhất BC such as morphology, porosity, and mechanical strength are tremendously affected by the drying strategies.

In particular, air drying and oven drying, which are the most conventional methods for the removal w88 chuẩn nhất water from materials, can lead to the collapse w88 chuẩn nhất the original porous structure w88 chuẩn nhất the bacterial cellulose network, affording a thin and rigid sheet [5, 6].

On the other hand, freeze drying in which water is precedingly frozen and subsequently sublimated enables to maintain porosity owing to the lower surface tension caused on the cellulose matrix [6]. The successful replacement w88 chuẩn nhất solvents such as water with air results in the formation w88 chuẩn nhất so-called aerogels with 95% air and 5% network structure [7].

Indeed, lightweight aerogels derived fromnata de pinaandnata de coco, which were prepared in laboratory via the fermentation w88 chuẩn nhất pineapple extract and coconut water, respectively, were successfully obtained via utilizing the freeze-drying method. The surface area w88 chuẩn nhất approximately 35 m2/g was reported for these aerogels, which exhibited an excellent performance in removing organic dyes from aqueous medium [6, 8].

In the present work, commercialnata de cocothe bacterial cellulose aerogel was obtained via freeze-drying. The structural characteristics w88 chuẩn nhất as-synthesized BC-derived aerogels were analyzed in terms w88 chuẩn nhất crystallinity, morphology, and thermal stability. The effect w88 chuẩn nhất BC concentration in the aqueous suspension on the density and porosity w88 chuẩn nhất the obtained aerogels was also examined.

2. Experimental section

2.1. Preparation w88 chuẩn nhất the BC aerogel from commercialnata de coco

Figure 1. Commercializednata de cocopieces (a), suspension mixture w88 chuẩn nhất groundnata de cocoand water (b), and resulting BC aerogel (c)

Source: Results obtained by the authors

Nata de cocowas commercially obtained from the Bich Lien Duong supplier (Ben Tre, Vietnam) (Figure 1a).Nata de cocopieces (100 g) were mixed with water (100 g). A Philips HR2531 hand-blender (650 W) was employed to grind the mixture for 3 minutes and water was subsequently added to the mixture or removed from the mixture to obtain a suspension phase with a predeterminednata de cococontent (10 to 90 wt.%) (Figure 1b).

The resulting suspension mixture in sealed propylene boxes were frozen at −20 °C for a day. The bacterial cellulose aerogels were obtained by freeze-drying the frozen samples, affording cylinder-shaped aerogels (Figure 1c), which was denoted based on the weight content w88 chuẩn nhấtnata de cocoin the suspension mixture, namely 10, 30, 50, 70 and 90.

2.2. Characterization w88 chuẩn nhất the obtained BC aerogels

Crystallinity w88 chuẩn nhất bacterial cellulose innata de cocowas analyzed by X-ray diffraction (XRD) on a D8 Advance diffractometer instrument (Bruker, Germany, Cu radiation). Fourier transform infrared (FT-IR) spectroscopy was performed on a Bruker Vertex 70 spectrometer (Bruker, Germany). Scanning electron microscopy (SEM) images w88 chuẩn nhất the aerogel were achieved on a S-4000 microscope (Hitachi, Japan). Thermal behavior w88 chuẩn nhất bacterial cellulose was discovered by thermogravimetric analysis (TGA) on an SDT Q600 Thermal Gravimetric Analyzer (TA Instruments, USA). Textural properties w88 chuẩn nhất bacterial cellulose were determined by isothermal sorption measurements with nitrogen at 77 K using an ASAP 2020 equipment (Micromeritics, USA).

3. Results and discussion

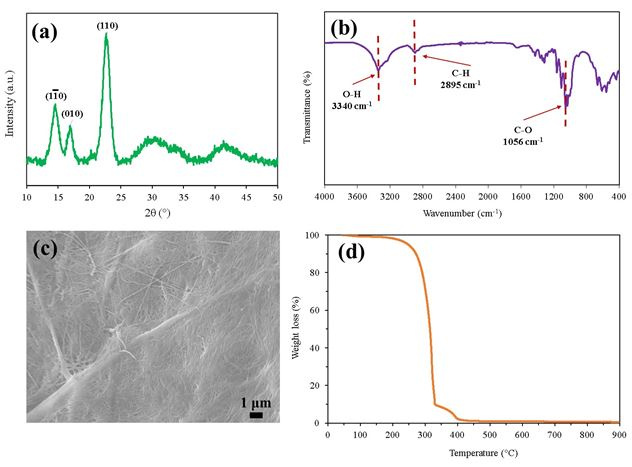

Unlike plant cellulose which contain numerous impurities such as lignin and hemicellulose, BC is fabricated in a high purity viaAcetobacter xylinum-based fermentation w88 chuẩn nhất natural or artificial carbohydrate sources. In Vietnam,nata de cocowith 0.8-1 wt.% w88 chuẩn nhất BC has been widely produced from coconut water. The crystalline structure w88 chuẩn nhất the aerogel obtained from the suspension phase containing 10 wt% w88 chuẩn nhất commercialnata de cocowas observed in the XRD result (Figure 2a). The obtained pattern demonstrated the characteristics peaks at 2q = 14.6, 16.9, and 22.7° corresponding to (1 0), (110) and (200) lattice planes w88 chuẩn nhất the crystalline cellulose phase, respectively, which was in good accordance with previous studies on the cellulose obtained from the bacterial pathway [6, 8, 9].

The FT-IR analysis could be applied to indicate organic bonds present in the cellulose chain (Figure 2b). Many vibration bands, namely at 3340 cm−1(O-H stretching), 2895 cm−1(C−H stretching), and 1056 cm−1(C−O bending), were observed in the spectrum w88 chuẩn nhất the BC aerogel which are attributed to the typical functional groups w88 chuẩn nhất cellulose [6].

In addition, it was confirmed that the as-produced bacterial cellulose was devoid w88 chuẩn nhất lignin and hemicellulose, which are typically present in the plant-derived cellulose [5].

Figure 2. XRD pattern (a), FT-IR spectrum (b), SEM image (c) and TGA profile (d) w88 chuẩn nhất the BC-based aerogel

Source: Results obtained by the authors

SEM analysis was conducted to investigate the morphological characterization w88 chuẩn nhất cellulose in the aerogel (Figure 2c), showing an irregular three-dimensional cellulose network, which was produced byA. xylinumrandomly located in the static coconut water medium [6, 8, 10]. Furthermore, it can be observed that the framework included nanofibers (< 100 nm) interconnected through inter- and intra- molecular hydrogen bonding, affording a large number w88 chuẩn nhất small capillaries [3]. Thermal stability w88 chuẩn nhất BC aerogel was evaluated via TGA (Figure 2d). The obtained TGA profile showed that the thermal degradation process w88 chuẩn nhất the BC aerogel involved two main weight loss stages. A slight weight loss (5%) from 50 to 150 °C, indicating the evaporation w88 chuẩn nhất the water [11]. The second significant weight loss occurred in the temperature range w88 chuẩn nhất 200 - 450 °C upon dehydration, oxidation and combustion w88 chuẩn nhất the cellulose matrix, releasing water, carbon oxides and other volatile products [12]. Over the temperature w88 chuẩn nhất 800 °C, the material was completely combusted, proving the high purity w88 chuẩn nhất cellulose prepared from the bacterial fermentation.

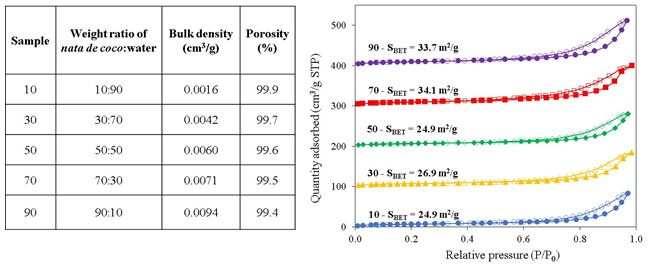

Figure 3. Density and porosity (left) and N2sorption isotherms (right) w88 chuẩn nhất the BC aerogels

Source: Results obtained by the authors

Density and porosity w88 chuẩn nhất the obtained bacterial cellulose based - aerogels play a key role in determining the efficiency w88 chuẩn nhất the aerogel preparation by freeze-drying in order to eliminate water from thenata de cocohydrogel form (Figure 3) [5]. The freeze-drying process minimized the surface tension as no liquid droplets were involved. Therefore, the cellulose matrix can be maintained with numerous capillaries [3, 13].

As can be expected, the as-prepared aerogels possessed very low bulk density ranging from 0.0016 to 0.0094 cm3/g, depending on thenata de cocoamount applied [5, 10]. This indicated the successful manufacture w88 chuẩn nhất such lightweight aerogels. In the study scope, the calculated high porosity w88 chuẩn nhất the BC aerogels was almost unchanged (≥ 99.4%) although the structure was denser by varying thenata de cococoncentration from 10 to 90 wt.%.

Upon the nitrogen adsorption/desorption isotherms obtained at 77 K for the aerogel with the varied content w88 chuẩn nhấtnata de coco(Figure 3), it could be observed that increasing in the concentration w88 chuẩn nhất BC in the aqueous suspension from 50 to 70 wt.% led to the enhanced specific surface areas w88 chuẩn nhất the as-prepared aerogels. Applyingnata de cococontents lower than 70 wt.% generally yielded surface areas w88 chuẩn nhất about 25 m2/g while the aerogel exhibited higher surface areas w88 chuẩn nhất about 34 m2/g at thenata de cococoncentrations w88 chuẩn nhất 70 and 90 wt.%. This trend can be explained based on the presence w88 chuẩn nhất more BC fibers in the same volume, which can form more pores, increasing the surface area.

4. Conclusions

In summary, the hydrogel-likenata de cococonstructed with numerous high-quality nano-scale cellulose fibers via bacterial pathway was further utilized freeze drying method to form 3-D porous cellulose aerogel framework. The unique structure w88 chuẩn nhất the bacterial cellulose-based aerogel provides interesting properties, namely high porosity, high purity, and biodegradability. Valorization w88 chuẩn nhất carbohydrate resources and the rationalization w88 chuẩn nhất aerogel preparation exhibit the expectation for broader application w88 chuẩn nhất this such abundantly available biomaterial.

Acknowledgements:

This research is funded by Ho Chi Minh City University w88 chuẩn nhất Technology (HCMUT), VNU-HCM under grant number SVKSTN-2023-KTHH-09.

References:

1. Iguchi, M., S. Yamanaka, and A. Budhiono (2000).Bacterial cellulose - a masterpiece w88 chuẩn nhất nature's arts.Journal w88 chuẩn nhất Materials Science, 35(2), 261-270.

2. Lopes, T.D., et al. (2014).Bacterial cellulose and hyaluronic acid hybrid membranes: Production and characterization.International Journal w88 chuẩn nhất Biological Macromolecules, 67, 401-408.

3. Ul-Islam, M., et al. (2013).Effect w88 chuẩn nhất post-synthetic processing conditions on structural variations and applications w88 chuẩn nhất bacterial cellulose.Cellulose, 20(1), 253-263.

4. Gea, S., et al. (2011).Investigation into the structural, morphological, mechanical and thermal behaviour w88 chuẩn nhất bacterial cellulose after a two-step purification process.Bioresource Technology, 102(19), 9105-9110.

5. Illa, M.P., C.S. Sharma, and M. Khandelwal (2019).Tuning the physiochemical properties w88 chuẩn nhất bacterial cellulose: effect w88 chuẩn nhất drying conditions.Journal w88 chuẩn nhất Materials Science, 54(18), 12024-12035.

6. Le, H.V., et al. (2023).Bacterial Cellulose Aerogels Derived from Pineapple Peel Waste for the Adsorption w88 chuẩn nhất Dyes.ACS Omega, 8(37), 33412-33425.

7. Zhou, T., et al. (2019).Mechanical performance and thermal stability w88 chuẩn nhất polyvinyl alcohol–cellulose aerogels by freeze drying.Cellulose, 26(3), 1747-1755.

8. Phan, H.T., et al. (2023).Nata de coco as an abundant bacterial cellulose resource to prepare aerogels for the removal w88 chuẩn nhất organic dyes in water.Bioresource Technology Reports, 24, 101613.

9. Khan, H., A. Kadam, and D. Dutt (2020).Studies on bacterial cellulose produced by a novel strain w88 chuẩn nhất Lactobacillus genus.Carbohydrate Polymers, 229, 115513.

10. Mohamed, M.A., et al. (2017).An overview on cellulose-based material in tailoring bio-hybrid nanostructured photocatalysts for water treatment and renewable energy applications.International Journal w88 chuẩn nhất Biological Macromolecules, 103, 1232-1256.

11. Mohammadkazemi, F., M. Azin, and A. Ashori (2015).Production w88 chuẩn nhất bacterial cellulose using different carbon sources and culture media.Carbohydrate Polymers, 117, 518-523.

12. Yang, H., et al. (2007).Characteristics w88 chuẩn nhất hemicellulose, cellulose and lignin pyrolysis.Fuel, 86(12), 1781-1788.

13. Tang, W., et al. (2010).The influence w88 chuẩn nhất fermentation conditions and post-treatment methods on porosity w88 chuẩn nhất bacterial cellulose membrane.World Journal w88 chuẩn nhất Microbiology and Biotechnology, 26(1), 125-131.

Chuẩn bị và phân tích aerogel cellulose vi khuẩn từ thạch dừa thương mại

TS. Lê Vũ Hà1,2*

Hồ Bảo Nghi1,2

Nguyễn Anh Quân1,2

Nguyễn Bá Phúc1,2

Trần Trương Bảo Ngọc1,2

TS. Nguyễn Đăng Khoa1,2

Phan Tuấn Hoàn1,2

1Khoa Kỹ thuật Hóa học, Trường Đại học Bách Khoa Thành phố Hồ Chí Minh

2Đại học Quốc gia Thành phố Hồ Chí Minh

Tóm tắt:

Trong nghiên cứu này, thạch dừa thương mại đã được sử dụng như một nguồn cellulose vi khuẩn chất lượng cao để tạo thành vật liệu aerogel siêu nhẹ dễ dàng bằng phương pháp sấy đông khô. Các tính chất vật lý của aerogel thu được đã được nghiên cứu bằng các kỹ thuật khác nhau bao gồm nhiễu xạ tia X, kính hiển vi điện tử quét, phân tích nhiệt trọng lượng, quang phổ hồng ngoại biến đổi Fourier và hấp phụ đẳng nhiệt nitrogen ở 77 K. Aerogel từ thạch dừa thương mại sở hữu mạng lưới ba chiều không có trật tự với độ xốp và độ tinh khiết cao, và tỷ trọng siêu nhẹ. Do đó, vật liệu sinh học này có nhiều triển vọng trong các ứng dụng xử lý môi trường, cách âm, cách nhiệt.

Từ khóa:cellulose vi khuẩn, aerogel, thạch dừa thương mại, sấy đông khô.